Dry Ice Blasting - "very nearly dustless blasting"

Sand Jet Cleaning

We specialise in using a low pressure sand jetting system that has been used nationwide for various cleaning tasks. The system, in our trained hands, causes minimal damage to an underlying surface and is flexible enough to tackle most property restoration cleaning tasks. The low pressure sand jet can clean surfaces without injecting large quantities of water into the surface, and with minimal surface damage, at the same time, the 'wet' system also captures dirt and abrasive, preventing the health and safety risks associated with dry blasting.

Dry Ice -'disappearing abrasive blasting'

However, there are times when alternative methods are called for, one of which is Dry Ice blasting. Here a surface to be cleaned is blasted with solid CO2 particles, and the surface is cleaned through thermal shock, the massive volume change as dry ice particles turn into gas, and some abrasion of the surface contaminant. A video of the process (cleaning soot from stone) is available cleaning soot from stone, and a data-sheet of property cleaning with dry ice cleaning property datasheet. and metal cleaning cleaning machinery data sheet This particular stonework was inside a fire damaged church near Grimsby, North East Lincolnshire.

The advantage of this system is that the 'abrasive' evaporates on impact, so the only 'debris' is the material being removed. It is nearly 'dustless' - about as dustless as it is possible to get for an open blast system - however it will still blow cobwebs, birds nests, paint debris etc. fairly liberally! It will also be noted in the photo above that we were using it to remove the soot from the glass as well - something you wouldn't try to do with a sand based machine!

Disadvantages are the costs compared to alternative systems, in particular the raw ingredient dry ice evaporates when it is not used, so needs to be used rapidly. On a daily basis, dry ice will cost 50% more than sand jet cleaning, but for the first day of a job, i.e. the mobilisation cost, is about 100% more. The other issue with the evaporation is that we have to gauge how much CO2 we will need the day before the job - and indeed tomorrow's order needs to be placed before 11am today - so if we run out with a job 'nearly complete' at 3pm, it will be the day after next before we can get more dry ice to complete it. , unlike sand blasting where we just take plenty of sand - and if we don't use it, it goes back on the pallet.

It is used widely in the printing industry to clean print rollers, and for mould and weld cleaning. We offer a mobile service and typically undertake dry ice blasting at your premises, be they in Nottingham, Derby, Yorkshire or nationwide.

Fire Damage

One of the main uses of Dry Ice cleaning is for fire damage restoration. And it must be said that it does do it very well - with soot rapidly cleaned from a surface leaving the surface clean. It is typically assumed by customers, specifiers, builders, insurers and the like that because the dry ice is a 'clean' product, then this is the cleanest way of removing the soot. But... although abrasive isn't added to the mix, all that soot is going to go somewhere (see this video - of this same wall being cleaned cleaning soot from stone) and as a dry dust it can spread very effectively. Sometimes the damp grit of our sand jet machine can capture the soot, and make for a cleaner job - with little damage and a much lower cost.

Metal Cleaning

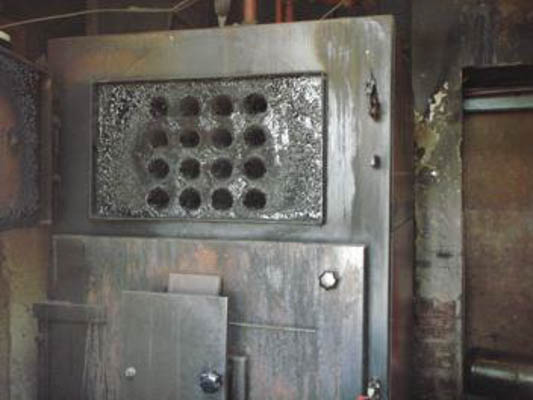

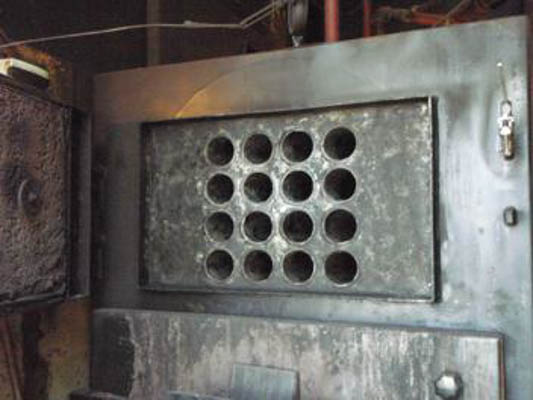

This was the result of leaving a wood burner boiler door ajar in a Grade I Listed Castle (there isn't a better word for it!) in East Yorkshire. There was a heavy tar build up on all metal surfaces - and indeed all round the room as well. Dry Ice cleaned it all very well (although the operator got liberally coated in soot in the process). Using grit blasting for the job would have resulted in a sand paper like finish on the metal, and an awful lot of sand in the room!

Soot from Paint

This shows that soot can be removed from 'fairly well adhered' paint - and the white paint was only limewash!

Brickwork

Soot and paint can be removed from brickwork with minimal damage to brick or pointing - with perhaps the caveat that if the brick is external - and a lot of water has penetrated the surface, dry ice can cause some ice damage to a wet surface.

Paint from Stone

The lime based paints were stripped from this Grade I listed bay window a few years ago. Nominally the first pair of bay windows in the property - because this room was empty of all other items. The paint did come off the mullions, and the stone remained intact... but the flakes of lime paint did also get fairly liberally spread round the room!

Marine Cleaning

Dry Ice will remove anti-foul from GRP boats - and was found in this trial to be very effective at bursting Osmosis blisters! It isn't cheap though - although the fun of popping this number of blisters by hand made it worthwhile!

Key Benefits

- A very 'clean' cleaning system. Cleaning chemicals / abrasives do not contaminate the work surfaces.

- It is not a chemical process so no noxious or harmful slurries or fumes are generated.

- The system is regularly used indoors, but good ventilation is required as the room fills with CO2, the risk of "confined spaces" is significantly increased.

- Considerably less mess than other systems.