Grit or Sand blasting Metal

A data sheet on our metal cleaning services, a suitable summary for printing is available in PDF format, Metal Cleaning Datasheet

We specialise in using a low pressure sand jetting system but obviously sometimes traditional sand/bead blasting is more appropriate for metal cleaning.

However The 'damp' system also captures dirt and abrasive, preventing the health and safety risks associated with dry blasting. It also acts as a coolant, and therefore can clean thin metals, such as motor vehicle shells, without heating the surface causing distortion.

A further advantage of the system we use is that it also uses much less abrasive than traditional sand or grit blasting, making expensive abrasives, such as garnet, cost effective, and more significantly reducing waste. Abrasive does not need to be recycled, preventing cross contamination between jobs, and apart from in specialist cases, is not a major part of the running costs.

But, one significant disadvantage of the 'damp' system is that flash rusting can quickly occur with iron or steel surfaces, so we offer traditional grit or sandblasting as alternatives or as a post blast 'flickover' to remove flash rusting. Traditional Sand blasting uses more abrasive, but is also more aggressive - making it typically faster too.

We have a blasting bay at our Beverley premises, enabling us to undertake some work in house and under cover. in this bay we can operate both our dry blast systems and the damp blast machines. (Please note that we do most of our work away on site, so please 'phone before arriving at our office with something to clean.)

These are a number of JCB hydraulic rams -that were unfortunately painted 'last season's' colours! - the yellow paint needed removing so that they could be repainted black.

On Site Preparation

A recovery lorry, dry blasted, Autumn 2017

Structural Steelwork

On site removal of existing paint, and priming of the bare steel - spring 2017

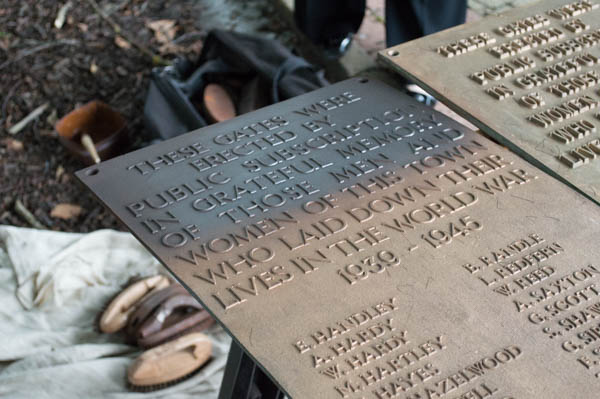

Bronze -War Memorials

Bronze war memorials bead blasted in situ, then patina replaced with new patination (by a subcontractor)

High Pressure Water

Radiators stripped of paint in a matter of minutes using high pressure water - compared to the hours they take with the sand jet!

Key Benefits

- The low consumption means that the system can be regulated to be gentle enough to clean delicate surfaces, yet powerful enough to strip multiple layers of paint in one pass.

- It is not a chemical process so no noxious or harmful slurries or fumes are generated.

- As it uses only minimal amounts of water and abrasive the system is regularly used indoors.

- Dry blasting available for applications where flash rusting is critically not required.

- Preparation of surfaces to SA 2.5

- Cold Galvanising of blasted steel structures