Industrial Cleaning - Building or Machinery Cleaning

With the regular downturns of the building sector, we have been called upon more to provide a cleaning and abrasive blasting service to industry. A data sheet on our industrial cleaning services is available data sheet on industrial surface preparation.

Preparation and Painting

We specialise in using a low pressure sand jetting system, obviously sometimes traditional sandblasting or bead blasting is more appropriate for metal cleaning. Equally pressure washing may sometimes suffice. We also offer priming of cleaned metals using Zinga or other primers (and currently we are very positive towards the moisture curing urethane products of Trident coatings)

The damp nature of our standard blast captures dirt and abrasive, preventing the health and safety risks associated with dry blasting. It also acts as a coolant, and therefore can clean thin metals, such as motor vehicle shells, without heating the surface causing distortion.

A further advantage of the system we use is that it also uses far less abrasive than traditional sand blasting, making expensive abrasives, such as garnet, cost effective, and more significantly reducing waste. Abrasive does not need to be recycled, preventing cross contamination between jobs, and apart from in specialist cases, is not a major part of the running costs.

We have a blasting bay at our Beverley premises, enabling us to undertake some work in house, and under cover. (Please note that as we do most of our work away on site, so please 'phone before arriving at our office with something to clean.)

Large storage tanks blasted and primed using Zinga in August 2008 - a simple tarpaulin minimised the debris field from the damp blast system - dry blasting would have spread debris all over the site.

Zinga cold galvanising was at this stage our standard treatment of blasted steel.

Moisture Curing Urethanes

A few years later and we discovered Moisture Curing Urethane primers and paints - just what we had been looking for as a complement to Zinga and to damp, slurry blasted steel. Trident Coatings are our supplier of choice. These paints are particularly suited to Blasting and painting in the United Kingdom - coping with foggy days where the humidity is high, bright sunny days, and indeed the depths of winter - we first used Moisture Curing Urethanes for a set of farm buildings with snow all around.

A fire damaged Warehouse cleaned and part primed using MCU Aluprime in Spring 2009

Painting

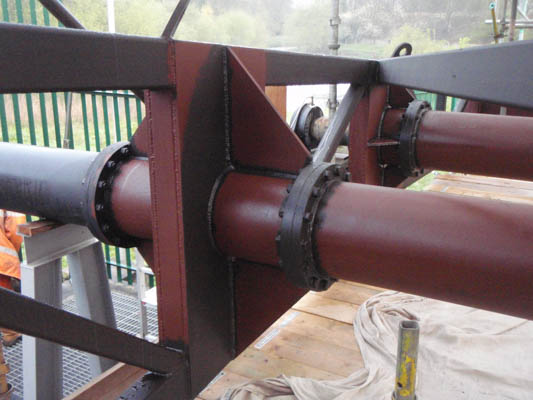

This is a motor body for a waste water pump in Hull's waste water pumping station. We spent quite a bit of one year cleaning metalwork in this station - then the pumps were delivered in not quite 'Yorkshire Water' blue - and we were asked to repaint them! We can offer an on site cleaning and re-painting service for machinery and site metalwork.

This was a flood defence dam down in Leicestershire. Rather than removing all the existing paint, 'rusty bits' were knocked off, the whole thing hot water pressure washed, then the surfaces treated to three coats of Moisture Curing Urethane 'Ferroguard'.

On Site Blasting

This was a pedestrian footbridge over a river near Darlington. Blasted in 2009. An impressive distance from the nearest road & water supply. Being over a river the sand jet came into its own with the minimal quantity of abrasive used and waste created.

On Site Blasting... and Priming

A farm water tank in Lincolnshire blasted and primed by us in 2015...

On site blasting, priming...and painting

Roof steelwork at a West Yorkshire Sewerage works - Autumn 2017

Confined Spaces

An evil job! Under a swimming pool in Sheffield - summer of 2016. The swimming pool water had been steadily leaking through the grouting between the tiles around the pool - this caused some 'significant' rusting and degradation in the structural steel below the pool - and it was our job to get into the impressively restricted spaces below the pool, blast the metalwork and prime the result - using MC Zinc - the moisture curing equivalent of Zinga - so that a fire protection company could follow up with an intumescent coat - god forbid that a fire should break out under a swimming pool!

Blasting Booth

We do have a blasting bay at our premises in Beverley. These were a large number of JCB's hydraulic rams that had been painted the wrong colour - our job was to simply get the yellow paint off so they could be painted the new 'black' standard. The manuafacture was based in Nottinghamshire - and we provided a collection and delivery service too.

Key Benefits

- The adjustable pressure mean that the system is gentle enough to clean delicate surfaces, yet higher pressures makes it powerful enough to strip multiple layers of paint in one sweep.

- It is not a chemical process so no noxious or harmful slurries or fumes are generated.

- As it uses only minimal amounts of water and abrasive the system is regularly used indoors.

- Preparation of surfaces to SA 2.5

- Cold Galvanising and priming of blasted steel structures